Traditional rebar cage assembly is predominantly a manual process, making it the most costly and time-consuming part of rebar processing and installation. Due to the high cost and complexity of manual rebar cage assembly at construction sites, industry professionals have been eager to find a modern solution that shifts the process from the construction site to a rebar processing center.

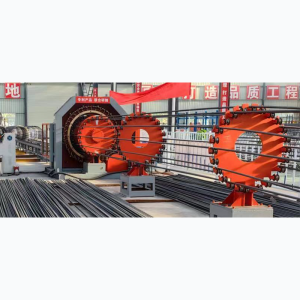

Volar machines were developed specifically to meet this demand. The patented "Volar System" technology offers an ideal solution for rebar cage assembly: by welding three longitudinal thin steel bars to the stirrups and linking them together, Volar equipment can weld at any position on the outer surface of the stirrups, allowing various shaped stirrups to be assembled into semi-finished beams and columns.

-

CNC STEEL CAGE WELDING MACHINE

VLHL-1200 Intelligent Reinforcement Cage Resistance Welding Production Line

Read more -

CNC STEEL CAGE WELDING MACHINE

VLHS Series intelligent steel cage welding and forming generation line

Read more

The processing is extremely simple:

- Insert the stirrups.

- The welding clamps connect the stirrups to the three longitudinal thin steel bars.

- Under computer control, the rebar cage automatically slides forward.

The process of tying the main bars has also been simplified: Since the stirrups are already fixed and spaced appropriately, tying the main bars only requires securing every 5-6 stirrups, greatly improving efficiency.

Key advantages:

- Using Volar equipment for rebar cage assembly takes only one-third of the time compared to traditional methods.

- It reduces processing costs by 65%.

- It offers high production flexibility and superior processing quality.

This rebar cage assembly solution is particularly suited for rebar processing centers and large-scale projects, significantly reducing labor costs and complexity on construction sites while ensuring efficient and high-quality production.