| model | - | VLHS-1500 | VLHS-2000 | VLHS-2500 | VLHS-3000 |

|---|---|---|---|---|---|

| Pile diameter | mm | Φ500-1500 | Φ800-2000 | Φ1100-2500 | Φ1100-3000 |

| Reinforcement cage length | m | Customized length according to customer requirements | |||

| Welding method | - | Carbon dioxide shielded welding, can be equipped with welding robots for automatic welding or resistance welding | |||

| Main reinforcement diameter | mm | Φ16-32 | Φ16-32 | Φ12-32/36 | Φ12-32/36 |

| Disc reinforcement diameter | mm | Φ6-12 | Φ6-12 | Φ6-12 | Φ6-12 |

| Reinforcement spacing | mm | 50-500 | 50-500 | 50-500 | 50-500 |

| Maximum weight of steel cage | kg | 4500 | 6000 | 8000 | 13000 |

| Hydraulic station pressure | MPa | 16 | |||

| Total power of equipment | kW | 11.2 | 14.2 | 22 | 28.5 |

| Equipment size | m | 27x1.9x2.4 | 27x2.5x3 | 27x2.9x3.4 | 27x3.5x4 |

| Total weight of equipment | kg | 10769 | 14317 | 15000 | 15612 |

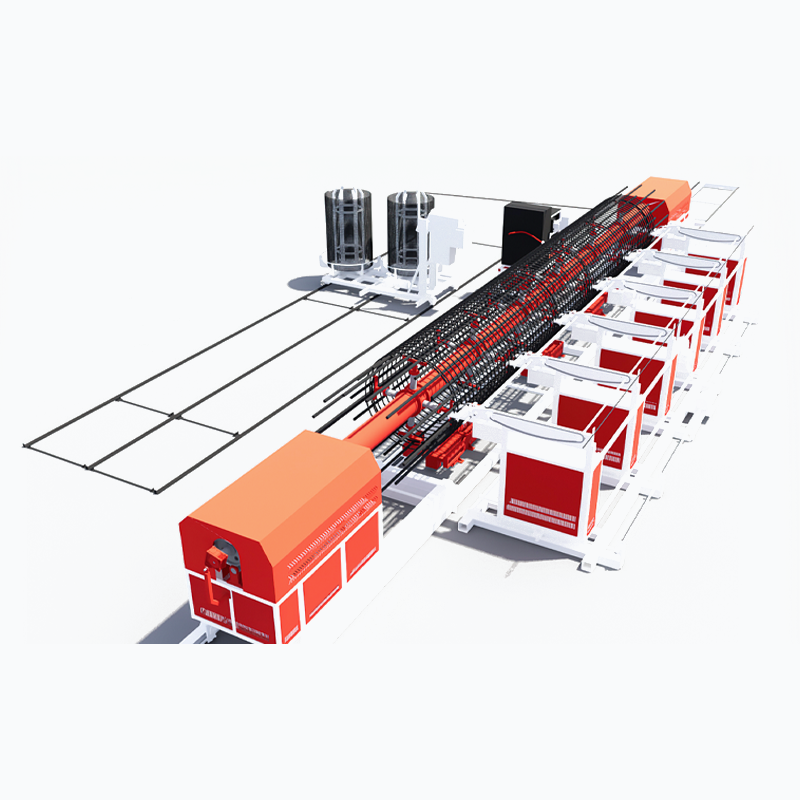

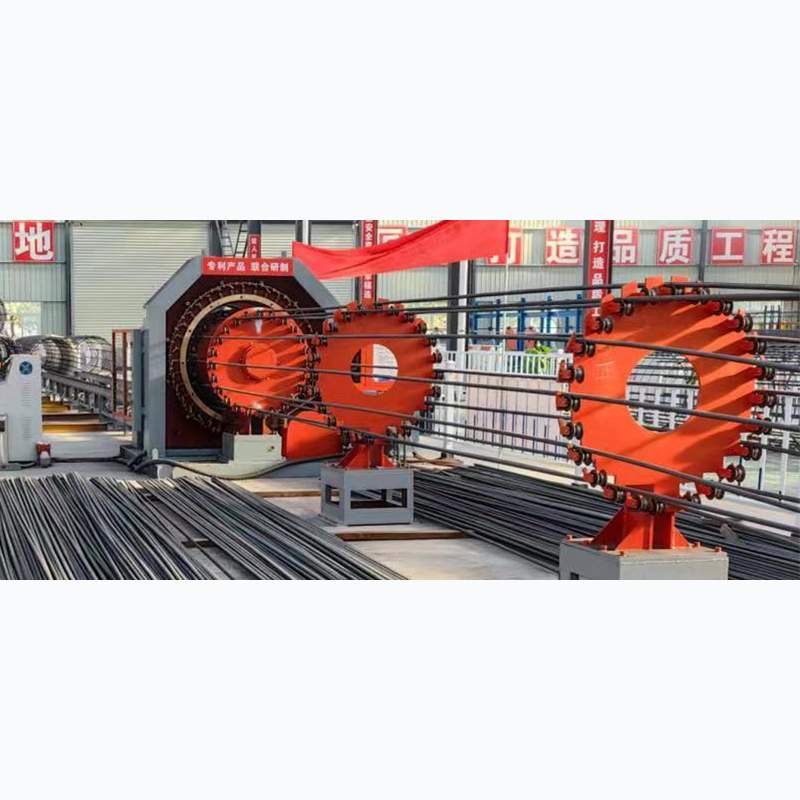

VLHS Series intelligent steel cage welding and forming generation line

Mainly used for subways, bridges, building construction, airports, highways, and foundation. This equipment is controlled by PLC and can automatically follow and weld steel reinforcement cages without the need for manual intervention during the process;

Frequently Asked Questions

To provide you with more convenience, we have compiled the most frequently asked questions about steel processing equipment machinery here. However, if you can't find what you're looking for in our FAQs, please call +8618937442315 or contact us via jimmyhan@volarmachine.com.