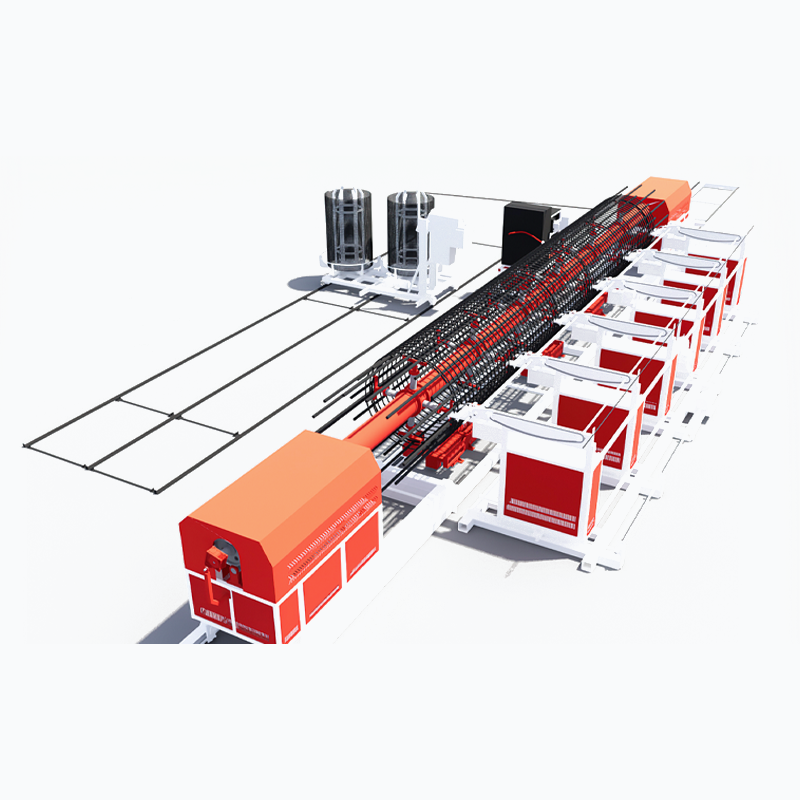

| Welding skeleton diameter | Ф 660- Ф 1060 (pile diameter: Φ 800- Φ 1200) |

|---|---|

| Welding steel reinforcement skeleton length | 3000-1300mm (according to user requirements) |

| Longitudinal diameter | Ф 16- Ф 32mm |

| Ring diameter | Ф 3.5- Ф 10mm |

| Ring diameter spacing | 5-150mm |

| Drive power | Wire winding motor Y160M-6 7.5KW variable frequency speed regulation |

| Wire feeding motor YLJ132-40-4 (torque motor) | |

| Traction motor YVP132M-4 7.5KW variable frequency motor | |

| Welding transformer power | 350KVA × 2 |

| Temporary load rate of welding transformer | 50% |

| Host power supply | 380V three-phase |

| Welding host speed | 0-20r/min |

| Cooling method for welding transformers | water-cooling |

| External dimensions (length x width x height) | 20000×2900×2420mm |

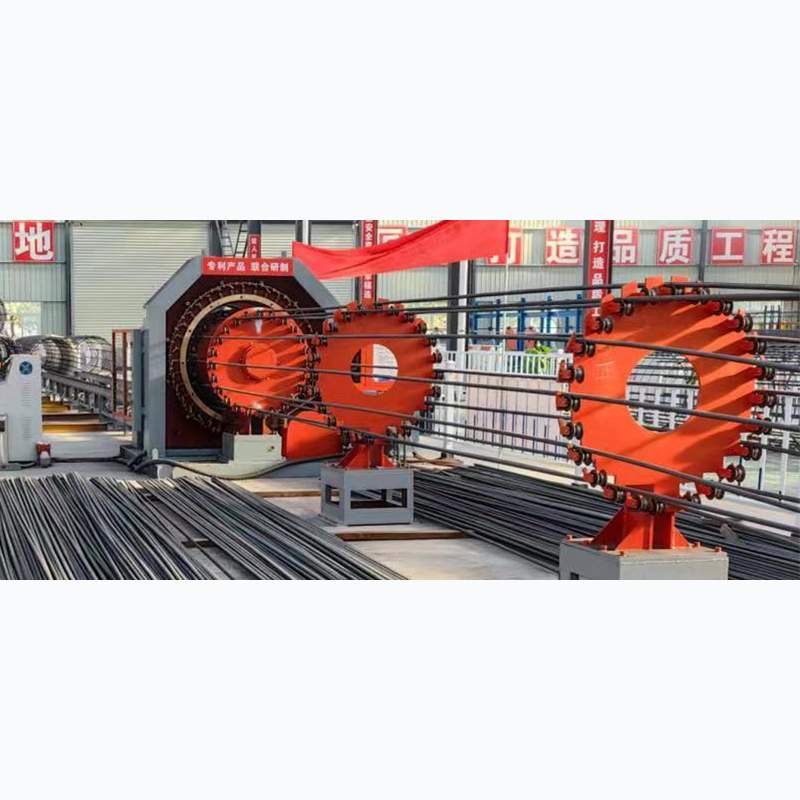

VLHL-1200 Intelligent Reinforcement Cage Resistance Welding Production Line

Mainly used for subways, bridges, building construction, airports, highways, and foundation. This equipment is controlled by PLC and can automatically follow and weld steel reinforcement cages without the need for manual intervention during the process; High welding efficiency, the welding time for each welding point can reach 0.7 seconds, saving two welders while significantly improving welding efficiency.

Frequently Asked Questions

To provide you with more convenience, we have compiled the most frequently asked questions about steel processing equipment machinery here. However, if you can't find what you're looking for in our FAQs, please call +8618937442315 or contact us via jimmyhan@volarmachine.com.