Product features:

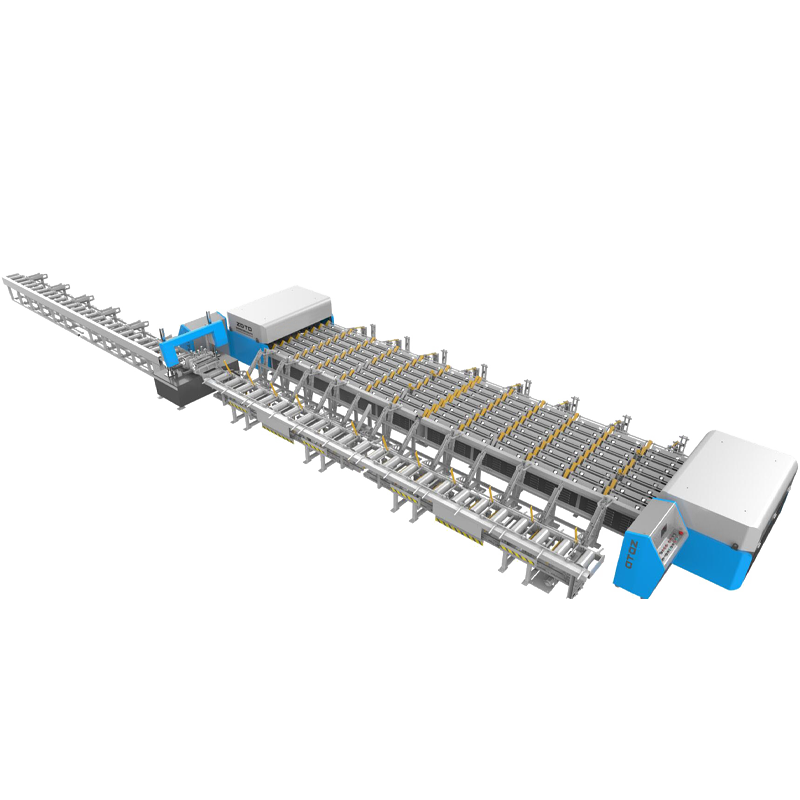

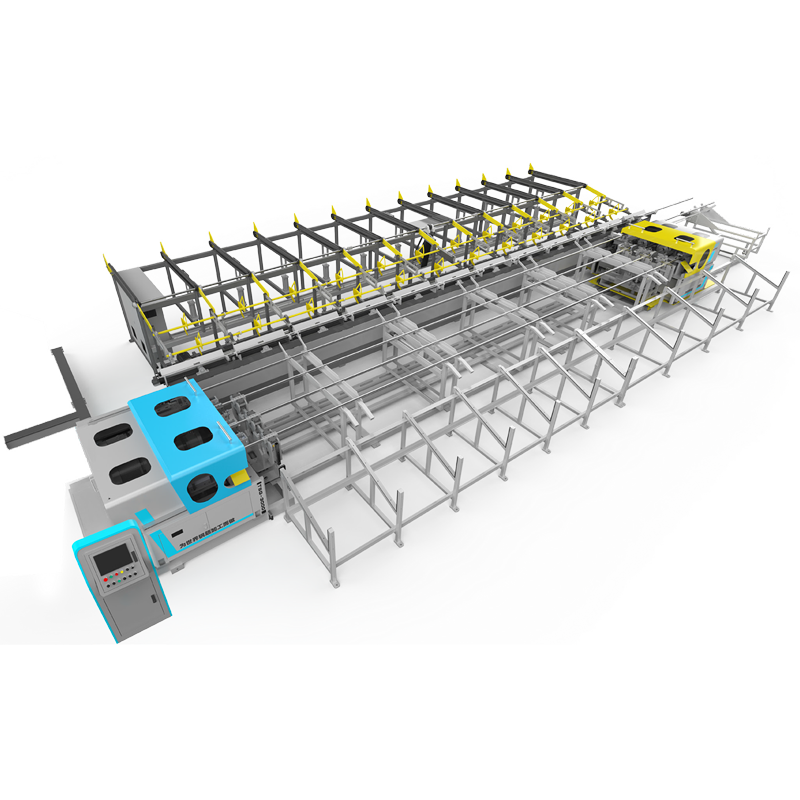

·The threading conveyor line is equipped with automated control for automatic feeding and high efficiency in automatic flipping. Ensure continuous automated production of bidirectional threading of steel bars;

·Upgrade the material sorting machine, automatically screen and distribute materials, ensuring the continuous automatic transportation and supply of steel bars to reduce labor intensity;

·The pier is thick, threaded, and polished, with a high degree of assembly, small volume, beautiful and safe appearance, and convenient installation and debugging;

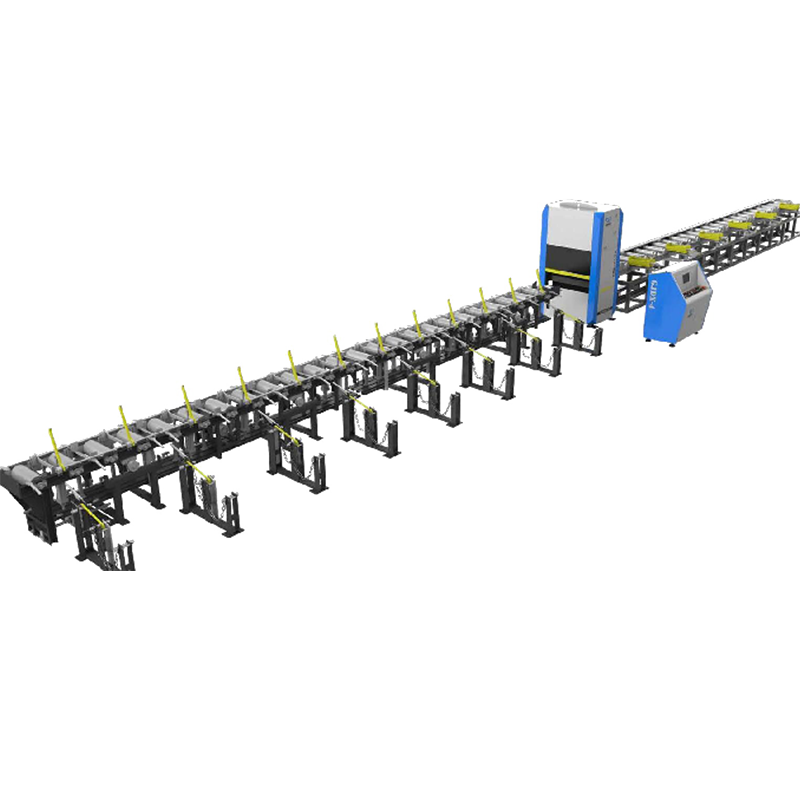

·Sawing machine, simple operation, high processing accuracy, and high efficiency;

·Automatic feeding line, convenient material transportation, reduces labor intensity;

·Dual level storage bin, capable of storing two different specifications of steel bars simultaneously;

·Unique milling and grinding two in one milling and grinding mechanism, strictly controlling the 4F accuracy of 0.6mm;

·The Huizhou coarse and threading hosts are equipped with the most advanced domestic host heads, which automatically clamp, feed, CNC coarse automatic demolding, rib pulling, and thread rolling;

·Electric control cabinet, with complete functions and beautiful appearance.

| model | VLTD-500 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Reinforcement diameter | mm | 16 | 20 | 22 | 25 | 28 | 32 | 35 | 40 | 45 | 50 |

| Sawing quantity | 根 | 26 | 20 | 18 | 17 | 15 | 12 | 11 | 10 | 9 | 8 |

| Blade speeds | mm/min | 7-10 (varies depending on the material and hardness of the sawn steel bars) | |||||||||

| Effective width | mm | The maximum cutting width of the sawing machine is 600; Effective width 450-500 | |||||||||

| Steel bar conveying speed | mm/sec. | 0.8-0.9 | |||||||||

| Cutting length | mm | <12 | |||||||||

| Length error | mm | +5 | |||||||||

| Pier diameter | mm | 25-32 | |||||||||

| Thread diameter | mm | 18-36, can customize raw material specifications above 36mm | |||||||||

| Emblem thickness length | mm | ≤ 90 | |||||||||

| Thread length | mm | <90 | |||||||||

| clamping system | Oil pressure+air pressure (high reliability, easy maintenance and upkeep) | ||||||||||

| Sawing motor power | kw | ten | |||||||||

| Huizhou rough machine power | kw | 7.5x2 | |||||||||

| Single head coarse time | sec | 22-30 | |||||||||

| Power of threading machine | kw | 5.5x2 | |||||||||

| Single head threading time | sec. | 30-50 | |||||||||

| Polishing machine power | kw | (3kW+0.75kW)x2 | |||||||||

| Single head polishing time | sec | 60-90 | |||||||||

| Number of silos | 2 | ||||||||||

| Total gas consumption | m?/min | 0.5-0.7 | |||||||||

| Total power of equipment | kw | 72.5 | |||||||||

| Equipment size | m | 28x9.25x1.55 | |||||||||

| Total mass of equipment | t | 21.5 | |||||||||