Product features:

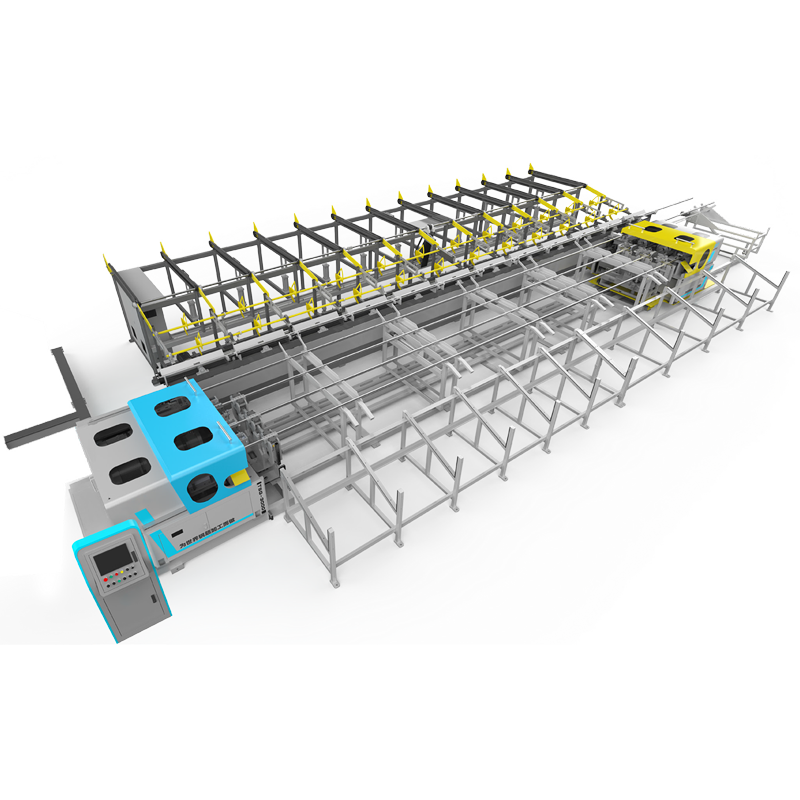

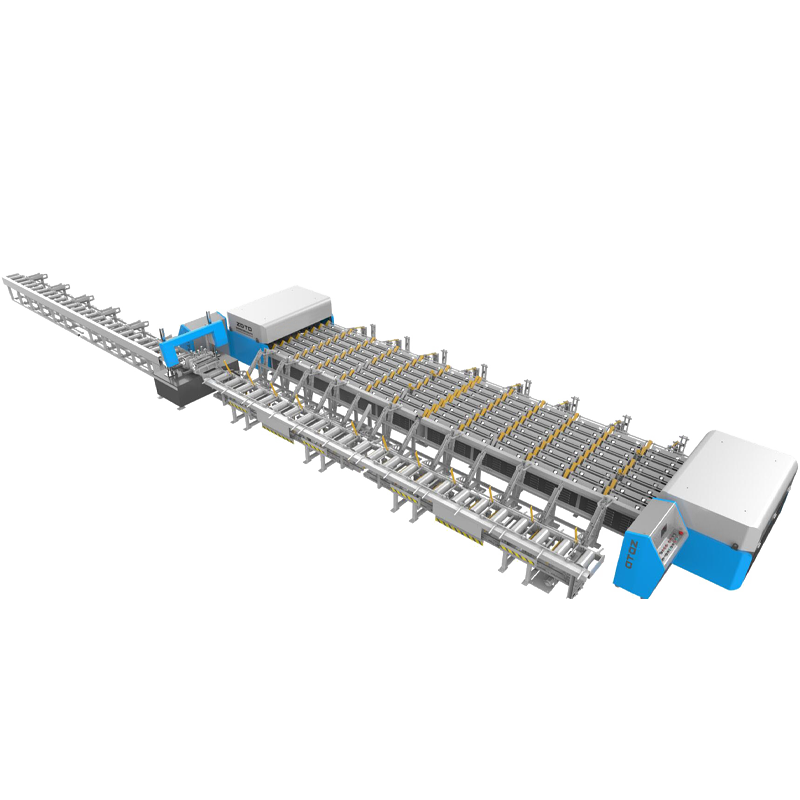

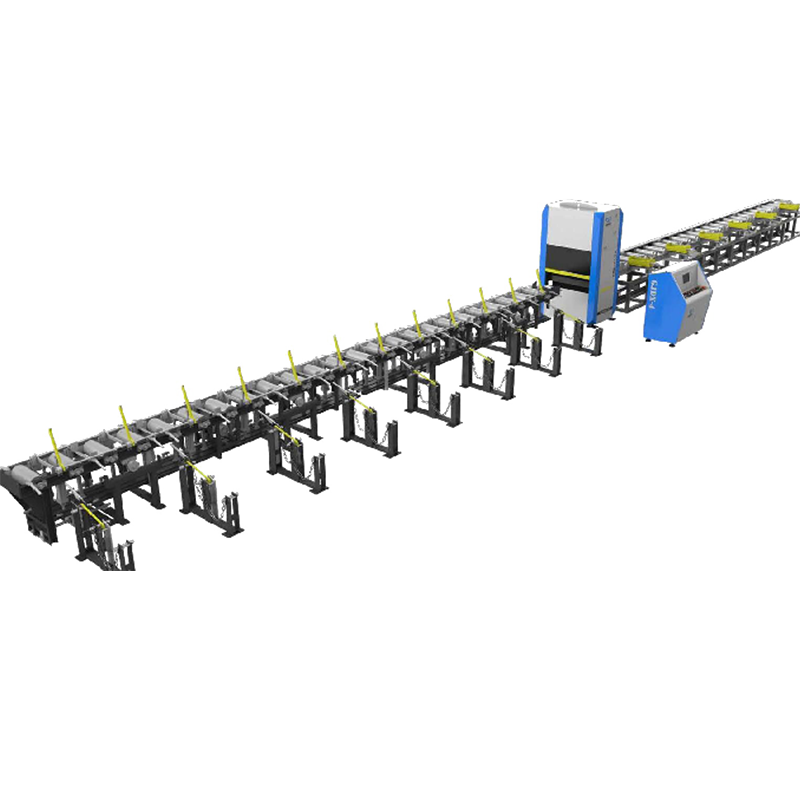

·The fixed threading and rib stripping machine head is designed with secondary positioning function and functions such as cutting, rib stripping, threading, and milling sections to form a four station assembly line, greatly improving product quality and work efficiency, and reducing production costs;

·Automatic feeder with automatic scattering, positioning, and orderly feeding functions, capable of adapting to Φ 16- Φ All threaded steel bars within a range of 50;

·The steel reinforcement surplus material mechanism can reasonably transfer and collect the function of longer steel reinforcement surplus material, to ensure a higher degree of equipment automation, adapt to a wider range of steel reinforcement length, and have higher efficiency;

·The human-machine intelligent interface control panel has the ability to issue commands, intelligently start and run, and also has storage functions, with a storage capacity of tens of thousands of job programs;

·The steel bar clamping mechanism has the function of steel bar clamping and synchronous transfer, ensuring that the steel bars complete automatic assembly line operation;

·Finished product receiving silo, with gentle impact and no noise, capable of storing 2-12 meters of steel bars;

·The middle lifting and pushing mechanism has the function of lifting and pushing steel bars for the world's steel processing surface, ensuring that the steel bars can be horizontally and parallel pushed forward, and ensuring more accurate rib stripping and threading length;

·Fixed threading and rib stripping machine head, and designed with automatic steel bar sizing function.

| Model | - | VLSG-3000 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Saw cut steel bar length | m | 6-12 | |||||||

| Length error | mm | ±2 | |||||||

| Thread diameter | mm | Φ16-40 | |||||||

| Thread length | mm | ≤ 90 | |||||||

| Efficiency of threading machine (double head) | s/pcs | 30 | |||||||

| Processing speed (double head) | pcs/h | 80-130 | |||||||

| Head movement speed | mm/s | 28-85 | |||||||

| Hydraulic working pressure | Mpa | 0-12 | |||||||

| Hydraulic flow rate | L/min | 23 | |||||||

| Total power of equipment | KW | 36.5 | |||||||

| Average power consumption | KW/h | 24.5 | |||||||

| Equipment size | m | 15×7.8×1.85 | |||||||

| Total mass of equipment | t | 8.5 | |||||||

| Reinforcement diameter | mm | 16 | 20 | 22 | 25 | 28 | 32 | 35 | 40 |

| Thread rolling wheel specifications | mm | 79×30×45 | 71×30×45 | 62.5×30×45 | |||||