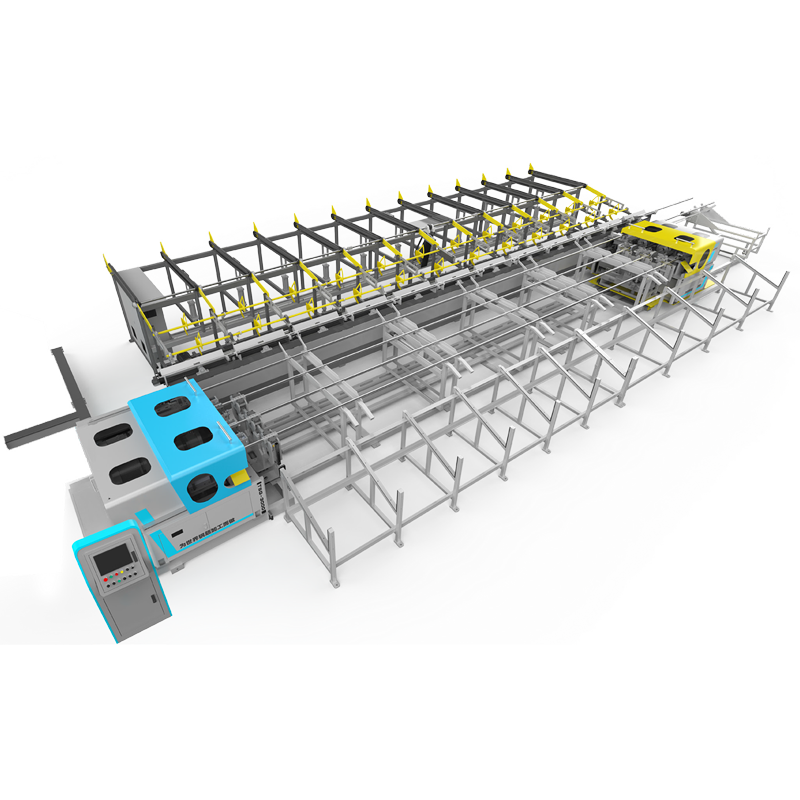

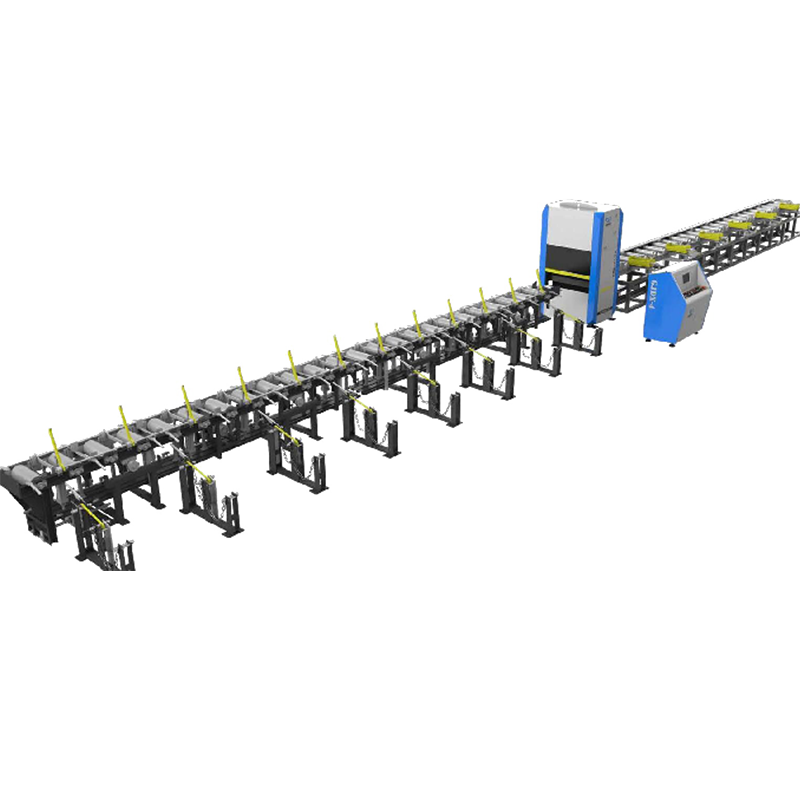

This machine is widely used in industries such as construction and highways, suitable for cutting and bending steel bars of various specifications and lengths. It can reduce auxiliary labor, reduce secondary handling, and achieve standardized length, accurate size, and high efficiency of processed products. It is a high-tech product independently developed by our factory with independent intellectual property rights. It is the first in China, with simple installation and convenient use. In short, we strive for diversity in design, meeting user needs, simplicity and effectiveness, in order to reduce costs, pursue the best cost-effectiveness, and bring tangible efficiency and benefits to users. Widely used in steel bar processing and distribution, national nuclear power construction, construction, as well as highways, railways and other fields.

Product features:

·Originating from the German technology control operating system, easy to operate;

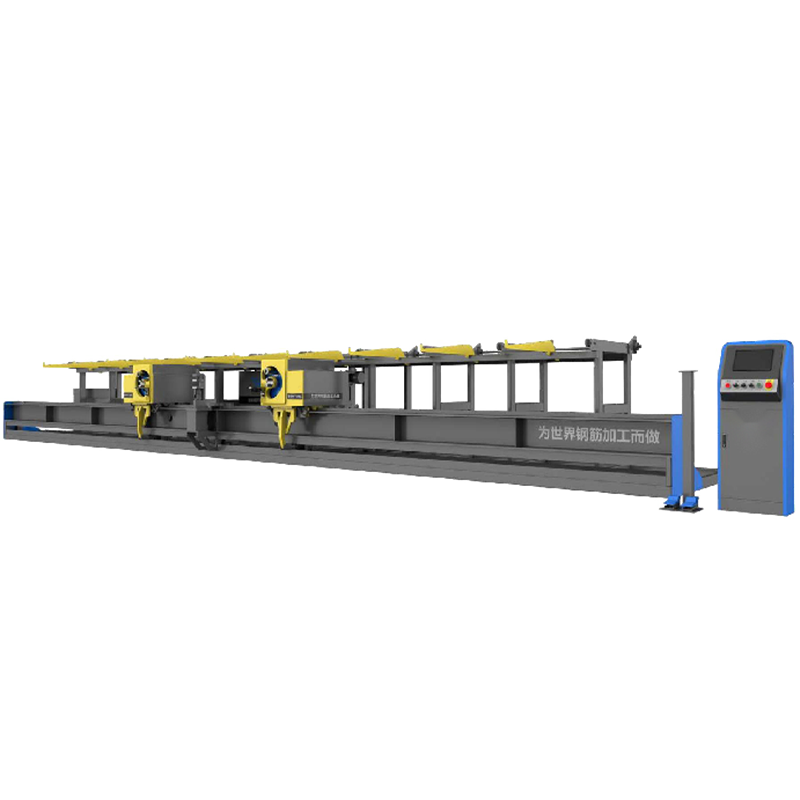

·Servo positioning system ensures molding accuracy and improves production efficiency;

·By using bending axes and bending molds, it can process steel bars of any shape with high efficiency;

·Mobile bending host with automatic length measurement for bending;

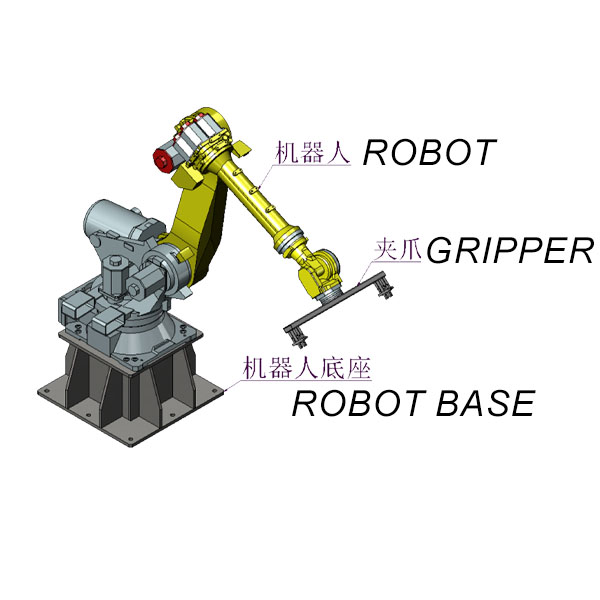

·Mobile robotic arm device reduces labor costs and is more efficient;

·High strength moving track, durable and long-lasting;

·Automatic cutting machine head, capable of bending multiple steel bars at once, with high production efficiency;

·The bending shaft and bending die are made of high-quality alloy materials and undergo heat treatment, with high wear resistance and long service life;

·Control system: Adopting PLC, touch screen, servo motor system, and frequency conversion system.

| Equipment model | HBZQW-32 | transfer speed | 60m/min | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Maximum shear force | 1250N | Total power | 28KW | |||||||

| Number of cutting actions | 30次 | Equipment size | 2600X2000X1700 | |||||||

| Maximum steel bar strength | 570 | Cutting length | 10-12000 | |||||||

| Bending speed | 360°/s | Bending mold | 3 sets | |||||||

| Total weight | 8t | |||||||||

| Shear bending ability | ||||||||||

| Reinforcement model | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | 28 | 32 |

| Number of steel bars | 4 | 4 | 4 | 3 | 3 | 3 | 2 | 2 | 1 | 1 |