| Number of robots | 4 end plate welding robots, 2 endboards grab robots, 1 cutting off robot |

|---|---|

| Word steel model | 14-22# |

| Long range of steel strings | 2.7-6.5m |

| Form -type steel radius range | ≥4 meters |

| High range of steel strings | ≤1 meters |

| Machining accuracy of steel arc length | ± 2mm |

| Cold bending speed | ≤4.5 m/min |

| Type steel cutting method | Plasma cutting |

| Welding efficiency of end plate (16#) | 4-5min/root |

| Welding robot model | Motoman-R1440 |

| Plasma cutting power | Hy120 |

| Plate -end steel -to -type accuracy | ± 2mm |

| Production efficiency (16#, 6M) | 15 roots/h |

| Total installed power | 62kW |

| power supply | 380V/50Hz |

| Operating temperature | -5~40℃ |

| Airway pressure | 0.6MPa |

| Dimensions | 36*11*2.1m |

| equipment weight | 25t |

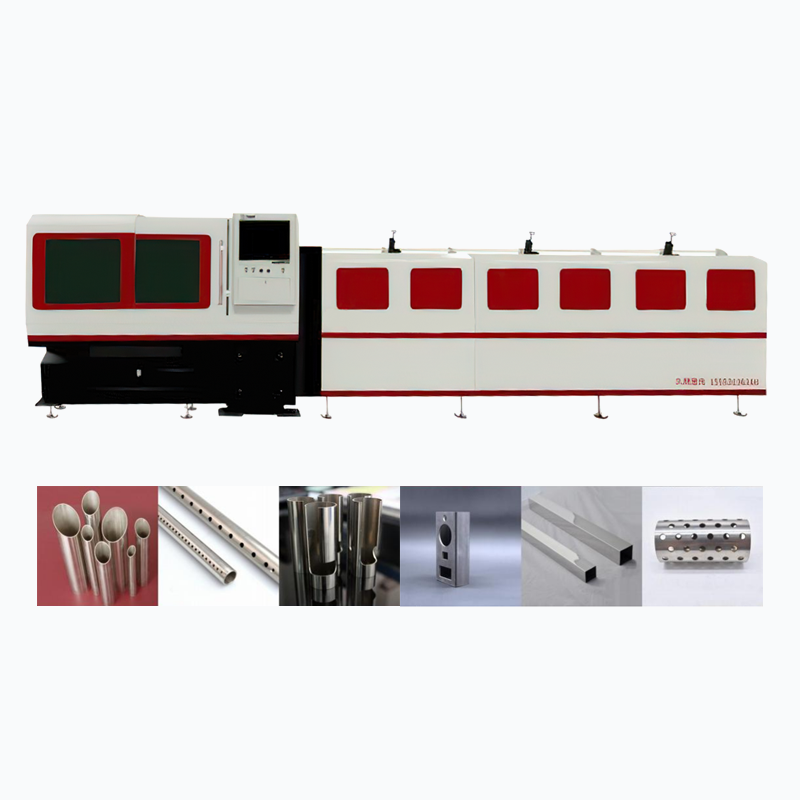

I Steel arch production line

CNC steel arched welding robot is 2 units of intelligent CNC control systems, 4 welded robots, 1 cutting robot, 2 capture robots, 5 laser cameras, 1 CNC plasma cutting power supply, 4 CNC welding machines, 4 CNC welding machines, and 4 CNC welding machines, and 4 CNC welding machines, and 4 CNC welding machines, 4 CNC welding machines, and 4 CNC welding machines, 4 CNC welding machines, and 4 CNC welding machines, 4 CNC welding machines, and 4 CNC welding machines. 1 set of material preparation modules, 1 set of steel conveying modules, 1 set of steel cold bending modules, 1 set of preparation module modules, 1 set of robot welding modules, and 1 set of finished products collection

Frequently Asked Questions

To provide you with more convenience, we have compiled the most frequently asked questions about steel processing equipment machinery here. However, if you can't find what you're looking for in our FAQs, please call +8618937442315 or contact us via jimmyhan@volarmachine.com.