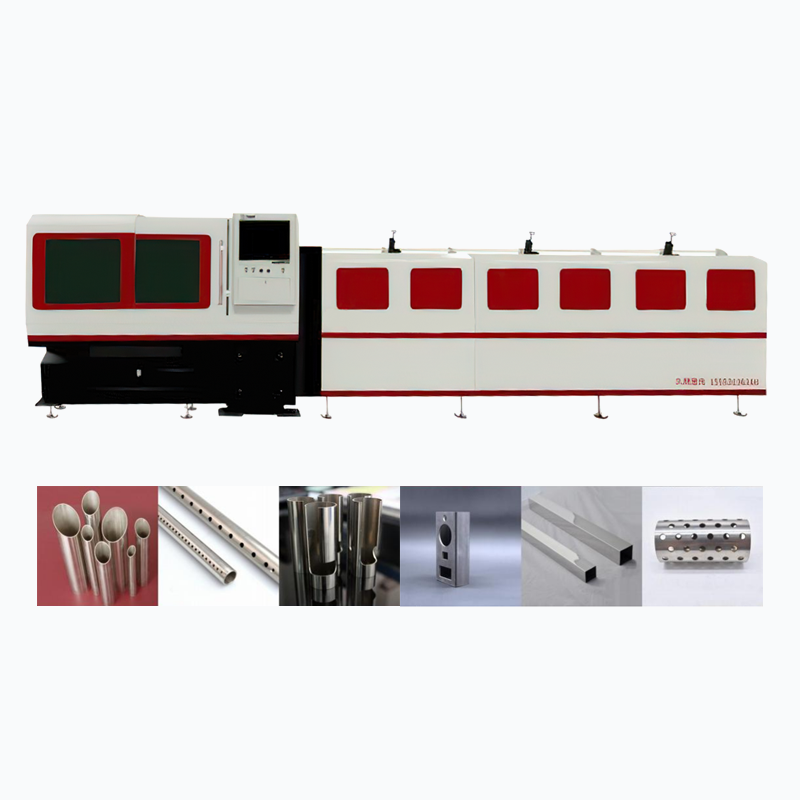

VLGZS-80/108 Small Tube Punching and Shrinking Production Line Product Introduction

Product Features

- High-Precision Processing

- Precisely processes steel tubes with diameters ranging from φ42 to 114mm, ensuring the accuracy of punching and shrinking sizes.

- Equipped with high-precision molds and positioning systems to effectively improve processing accuracy and reduce errors.

- High-Efficiency Production

- Production speed can reach 1200 - 2400 holes per hour, greatly enhancing production efficiency.

- Fast movement speed of steel tubes (10 - 565mm/min) shortens the processing cycle.

- Flexibility and Versatility

- Applicable for processing steel tubes of different lengths (2 - 9.5m), meeting diverse production needs.

- Capable of processing various hole diameters (φ6, φ8), offering more options.

- Energy Conservation and Environmental Protection

- Average power consumption is low: 37kW/h for the VLGZS-80 model and 78.5kW/h for the VLGZS-108 model, effectively reducing production costs.

- Optimized design and energy-saving components reduce energy waste and comply with environmental protection requirements.

- Stability and Reliability

- A sturdy structure and high-quality materials ensure the equipment's long-term stable operation.

- An advanced control system enables automated operation and reduces human errors.

Application Fields

- Widely used in tube processing in industries such as automotive manufacturing, furniture manufacturing, architectural decoration, and hardware products.

After-Sales Service

We provide comprehensive after-sales services, including equipment installation and commissioning, operator training, regular maintenance, and timely technical support. This ensures that you have no worries during use and maximizes the return on your investment.