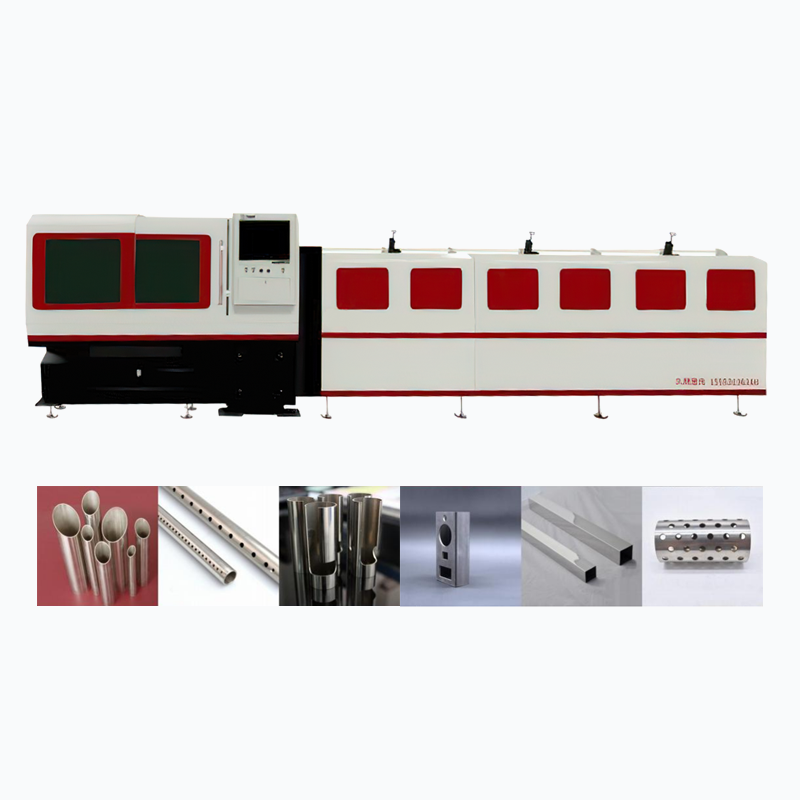

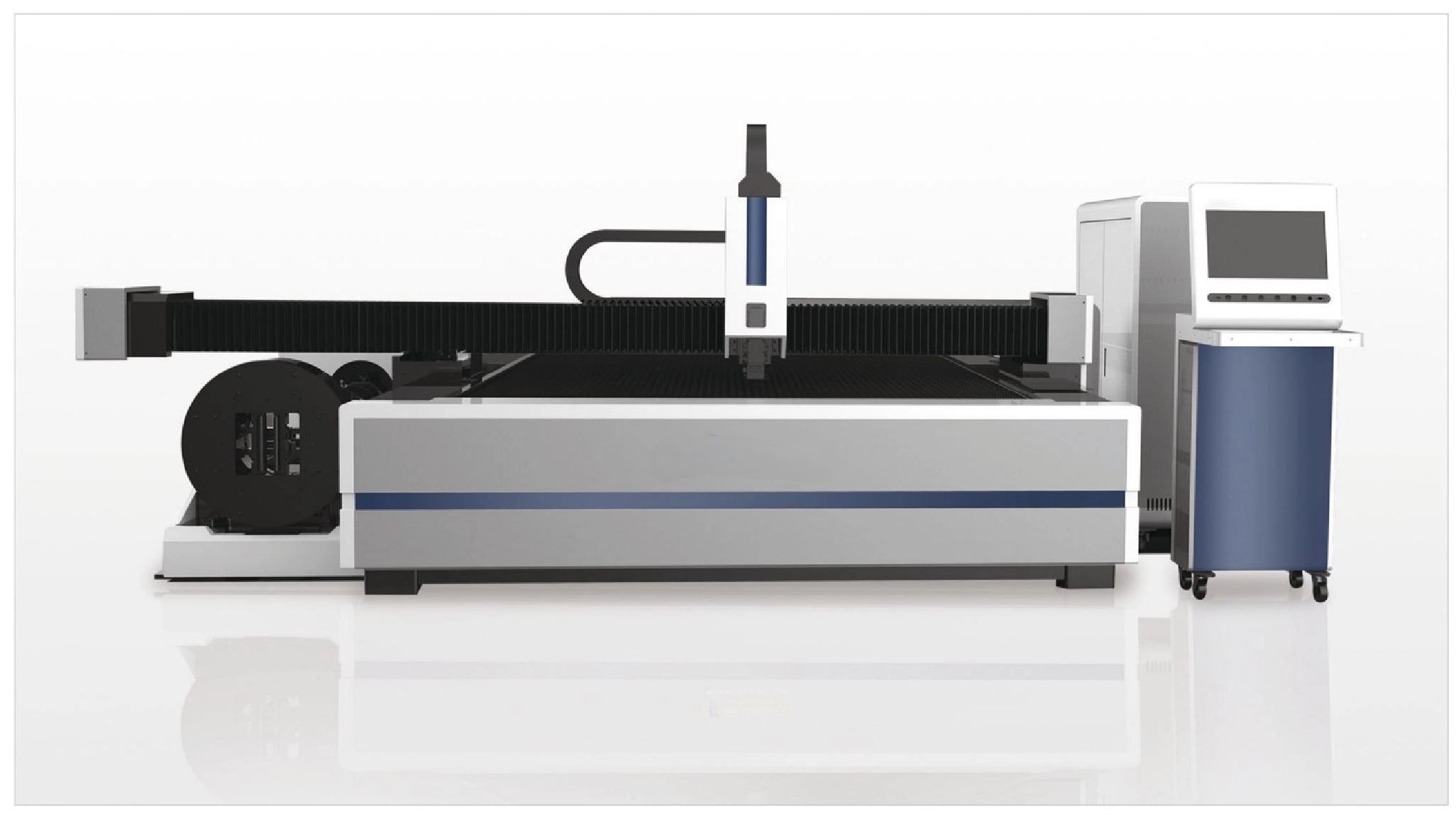

Three -dimensional five -axis high -speed laser cutting machine

Laser Cutting Machine Main Features:

- Short Tail Material: 150mm

- Fully Automatic Unloading (Optional)

- Versatility: Capable of cutting round tubes and square tubes of different types.

- Built-in Suite Software: Enables quick programming.

- Self-Developed System: Supports bus communication, offering fast response, simple operation, and customizable development.

- High Precision Cutting: Uses laser beams for cutting, providing smooth, burr-free edges with high accuracy, suitable for various complex shapes and detailed patterns.

- Tube Cutting Range: Round tubes φ15-85mm; square tubes 15x15-60x60mm.

- High-Speed Operation: Equipped with an efficient servo drive system and advanced motion control technology, it achieves fast cutting speeds with acceleration up to 1.6g, making it suitable for large-scale industrial production.

Applications:

- Aerospace: Precision machining of aircraft components, such as sheet metal parts and structural components.

- Automotive Manufacturing: Suitable for cutting automotive parts, including body panels and chassis components.

- Electronics: Precision cutting of electronic product casings and components.

- Medical Devices: Ideal for manufacturing medical devices, such as surgical instruments and implants.

- Architectural Decoration: Used in processing building materials, such as decorative panels and structural components.

Equipment Advantages:

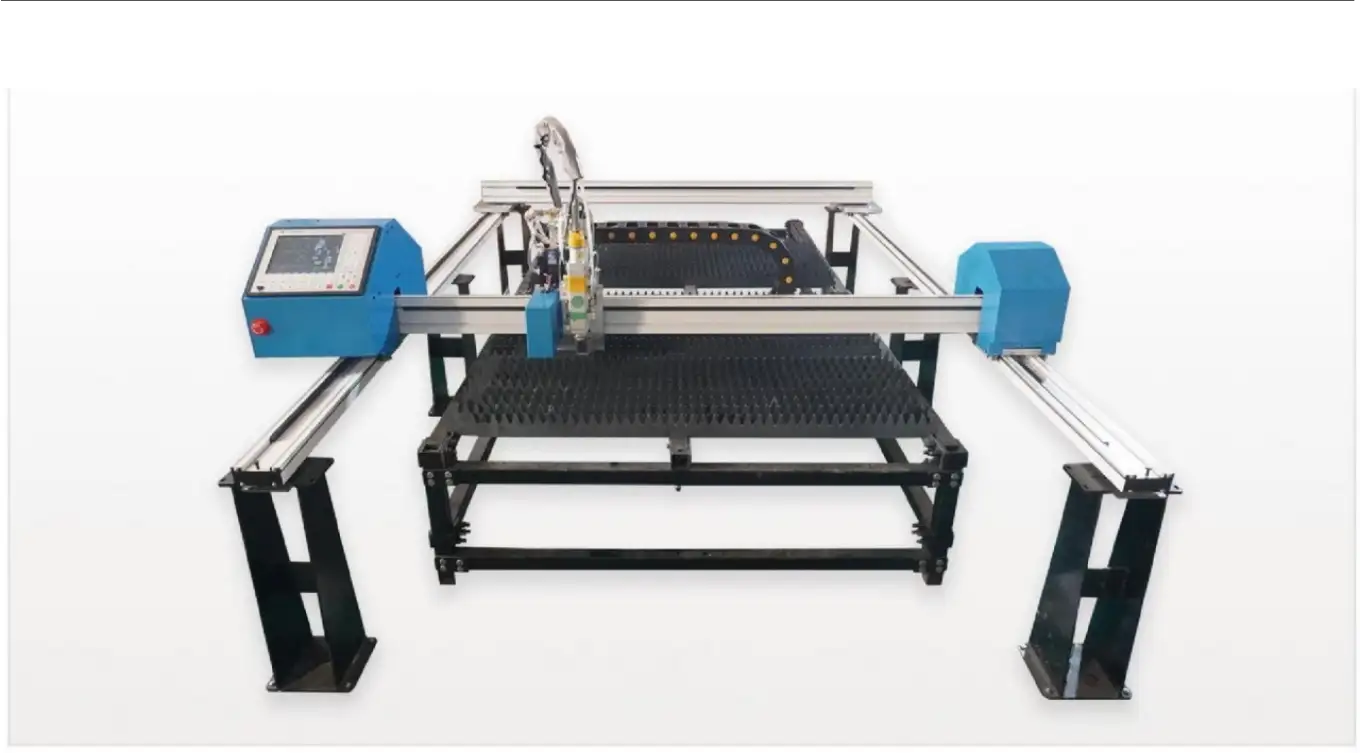

- High Degree of Automation: Equipped with advanced automation control systems, capable of automatic loading and unloading, and automatic adjustment of cutting parameters, ensuring easy operation.

- Energy Efficient and Environmentally Friendly: Utilizes high-efficiency laser sources with low energy consumption, meeting environmental standards.

- High Flexibility: Modular design allows for configuration and adjustment based on different processing needs.

The advent of the Three -dimensional five -axis high -speed laser cutting machine has brought new processing methods to high-end manufacturing, significantly improving production efficiency and machining accuracy, making it an indispensable tool in modern industrial production.