| model | VLGH-2080 | ||

|---|---|---|---|

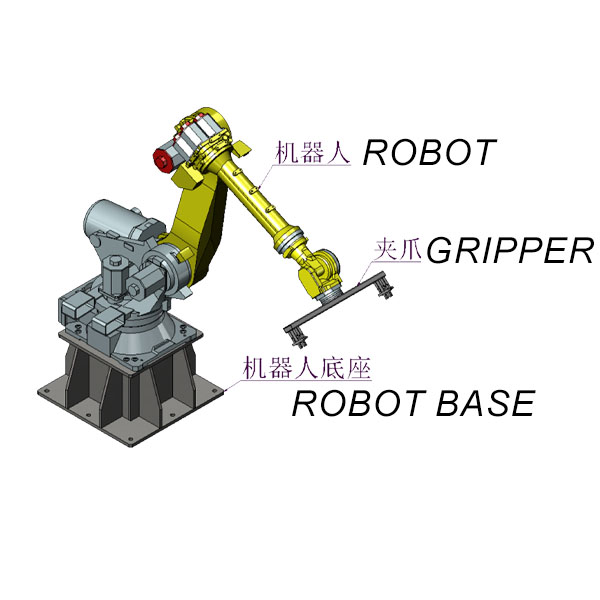

| Robot axis | 一 | 6 | |

| Stretching distance | mm | 1445 | |

| Maximum hand load | kg | 6 | |

| Arm rotation | ° | ±165 | |

| Arm front and back | ° | +150-90 | |

| Up and down arms | ° | +90-175 | |

| range of motion | Wrist rotation | ° | ±180 |

| Wrist Flexion | ° | ±135 | |

| Wrist torsion | ° | ±260 | |

| Arm rotation | °/s | 240 | |

| Arm front and back | °/s | 240 | |

| Rotation speed | Up and down arms | °/s | 220 |

| Wrist rotation | °/s | 430 | |

| Wrist Flexion | °/s | 430 | |

| Wrist rotation | °/s | 650 | |

| ambient condition | ambient temperature | ℃ | 0-45 |

| relative humidity | % | 35-85(No condensation) | |

| Walking speed | m/min | 4 | |

| Average power consumption | kW/h | 8 |

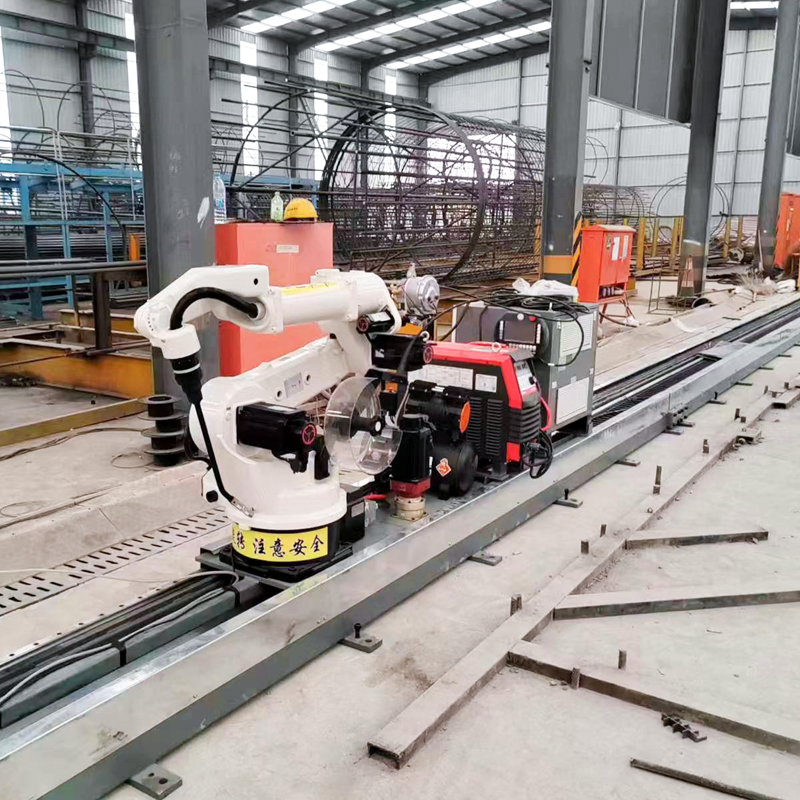

VLGH-2080 BRIDGE COVER BEAM SKELETON SLICEWELDING ROBOT PRODUCTION LINE

Features:

(1) Smart robot operations are simple and fast. Ordinary workers can operate and automatically weld the operation, which greatly reduces workers' labor intensity.

(2) Smart robot welding quality is high, the weld is full and beautiful, and the quality is constant.

(3) Robotics can work without intermittent day and night operations, with high efficiency and low management costs.

(4) Intelligent equipment enhances the engineering image and realizes engineering intelligence.

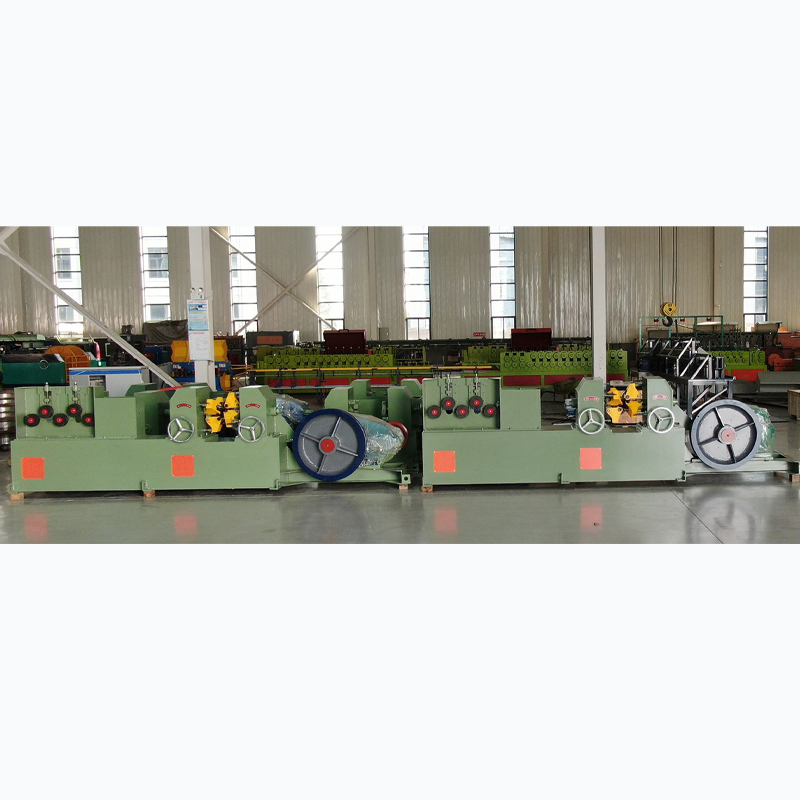

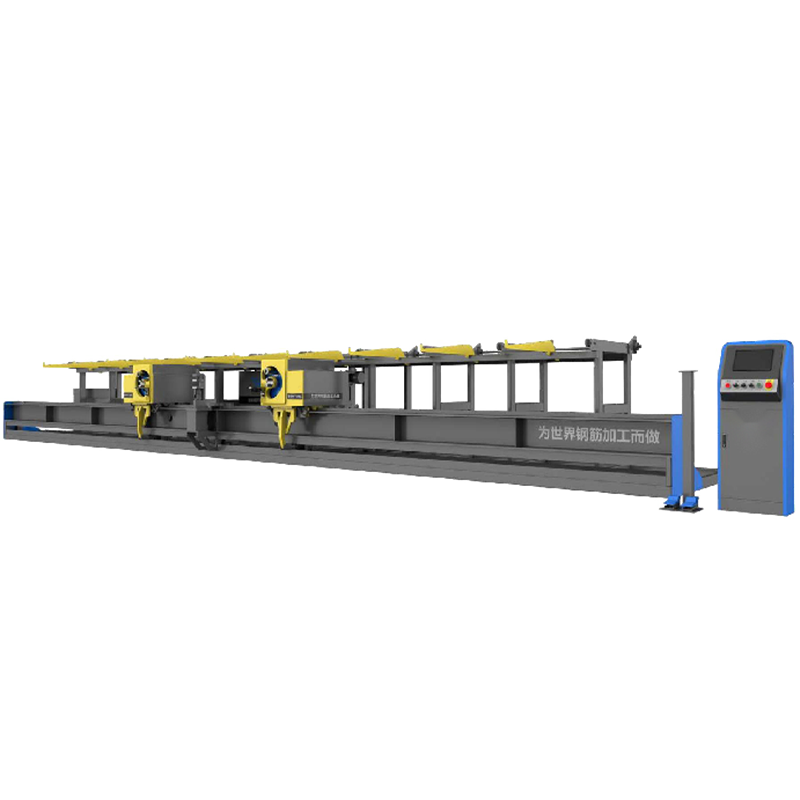

Related Products

Frequently Asked Questions

To provide you with more convenience, we have compiled the most frequently asked questions about steel processing equipment machinery here. However, if you can't find what you're looking for in our FAQs, please call +8618937442315 or contact us via jimmyhan@volarmachine.com.